Technology & Innovation

Technology & Innovation

Technology & Innovation

OMI GROUP

OMI System Engineering

Activities

Industrial Sector

(Design of machines, plants and equipment.

Structural FEM analysis

Design of safety systems and general plant engineering for Rail

Automotive Sector

(Development and industrialization.

Development and efficiency improvement Processes)

OMI Tools

Activities

Industrial Sector

AutomotiveSector

Rail Sector

(Design and Construction of Molds and Production Equipment)

OMI Industrial

Activities

Industrial sector

Automotive sector

Rail sector

(Manufacture of Plastic Components for Thermoforming

Manufacture of Plastic Components for Injection)

Cannon foaming plant for PU parts

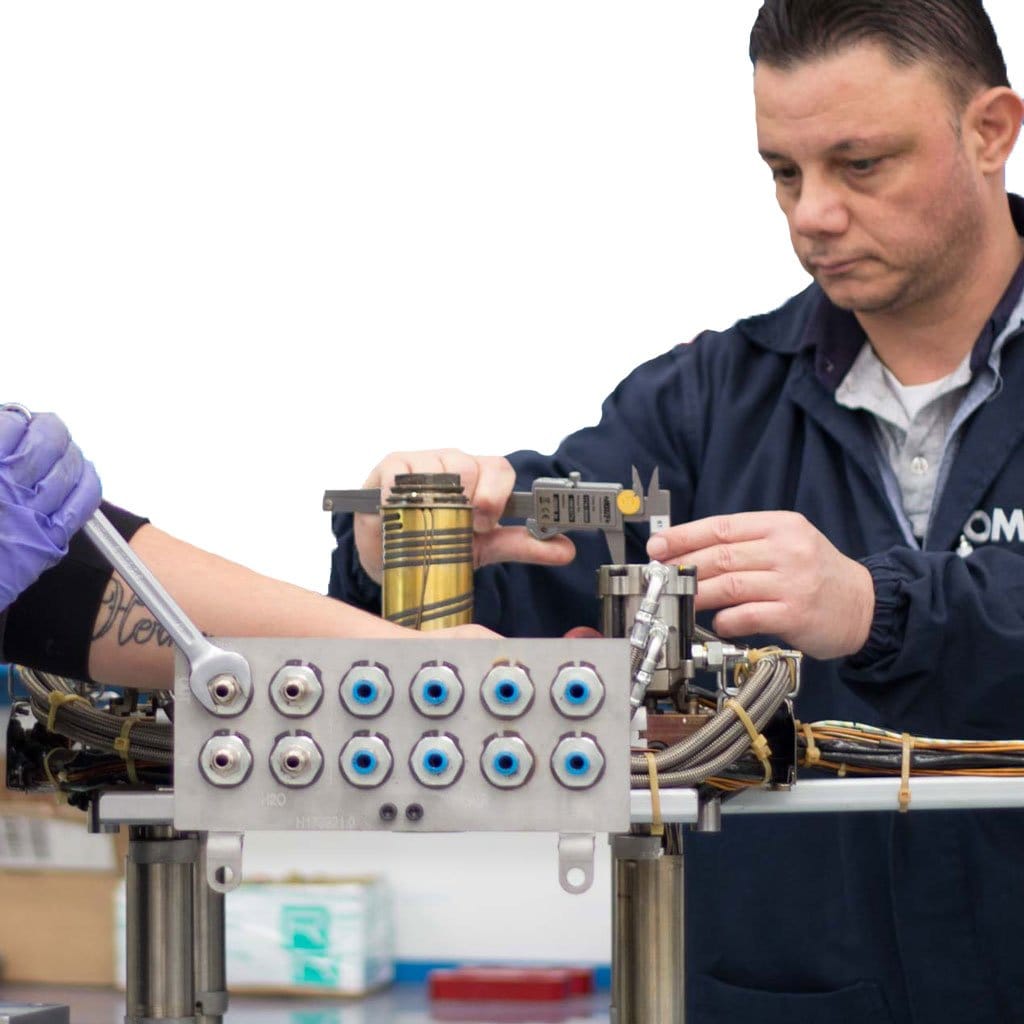

OMI System Engineering

Design and Simulations

Design has, always, been the core business of Omi Group. The Engineering Division has more than two decades of experience, hundreds of completed projects and satisfied customers all over the world. Design activities cover the naval, aviation, railroad, truck, and household appliance segments, while specializing in the automotive sector.

Partner companies turn to OMI Group for the design of plants, equipment, complete molds and turnkey systems, always verified and guaranteed.

OMI Tools

Molds, fixtures, control gauges, waterjet templates, presses, and prototypes

The Tools division specializes in the production of molds and tooling that lend themselves to a wide variety of applications and, in particular, to the manufacture of interior and exterior parts of automobiles.

In addition, the OMI Group is involved in the creation of systems for the assembly, finishing and final inspection of manufactured parts through highly technological systems.

In addition, OMI Tools boasts the production of prototypes, series molds and pre-series samples of thermoformed parts, polyurethanes and plastic injection.

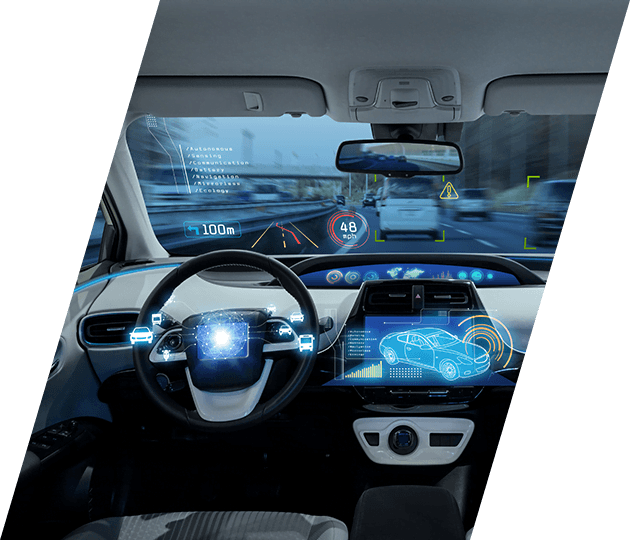

Technology & Innovation

In collaboration with

The Faculty of Science of the “Università Politecnica delle Marche” (UNIVPM) and the Department of Chemistry of the “University of Salerno” (UNISA) for the development of technologies and new materials.

OMI Gest & Control Systems

OMI Group has developed OMI Gest, software that can track and control the entire production flow, and OMI Control Systems, a laser control arm that takes high-precision measurements.

OMI Industrial

Thermoforming, plastic parts and polyurethanes

The Industrial division specializes in thermoforming and production of plastic and polyurethane parts. The manufacturing process for thermoforming, plastic parts, and polyurethanes begins in the engineering division where a team of highly skilled engineers designs and develops the equipment that will be made by the Tools division. From the Tools division we come to Industrial, where pre-series and true series production of interior and exterior components, acoustics and thermals for cars and industrial vehicles takes place.